| Product Introduction: | End epoxy silicone oil is a linear polydimethylsiloxane containing epoxy functional groups at one or two ends. Due to the presence of active epoxy groups at the end groups, it is often designed as a reactive modifier for organic resins and an important intermediate raw material for block polymers. The end epoxy silicone oil prepared by our company using a new method not only has a higher epoxy value compared to ordinary end epoxy silicone oil in the market, but also has more significant reactivity and extremely high cost-effectiveness. |

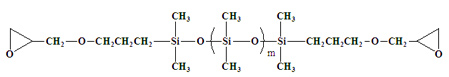

| Structural formula: |  |

| Common Models And Indicators: | Quantum viscosity (25 ℃, mpa.s) Appearance content epoxy value (mol/100g) Density PH6000120 ± 10 Slightly brown transparent to slightly turbid oily liquid>99% 0.030 ± 0.002-0.976-78000170 ± 10 Slightly brown transparent to slightly turbid oily liquid>99% 0.024 ± 0.002-0.0976-71000250 ± 20 Slightly brown transparent to slightly turbid oily liquid>99% 0.018 ± 0.002-0.0976-713000400 ± 30 Slightly brown transparent to slightly turbid oily liquid>99% 0.015 ± 0.002-0.976-7 |

| Product Usage: | 1. By reacting with the epoxy groups contained in the end groups, the organosilicon properties are introduced into organic resins, especially in epoxy resins to enhance toughness, improve electrical performance, and reduce internal stress. 2. The important intermediate raw material of organic silicon block polymer is the key raw material for the new generation of ternary copolymer silicone oil softener used in textile printing and dyeing. Its finished product overcomes the shortcomings of ordinary amino silicone oil such as yellowing and emulsion breaking and roller sticking. 3. Excellent demolding effect, it is an ideal material for epoxy resin internal and external demolding agents. 4. Good affinity for fibers and fillers, with a similar effect to silane coupling agents, can increase interfacial bonding strength and improve the strength of composite products. 5. A broad-spectrum tackifier for adding silicone rubber, which is very effective in increasing the viscosity of aluminum and glass. |

| Packaging And Storage: | 200L plastic/iron drum packaging, net weight 190KG, special specifications can be contacted with the company. |

| Product Transportation And Storage: | 1. When storing, do not come into contact with open flames. Keep it ventilated and dry. Do not come into contact with acids or alkalis. Store at a temperature The temperature ranges from -45 ℃ to 45 ℃. 2. During transportation, be protected from rain and sunlight. Storage and transportation of dangerous goods. |

Record Number:Su ICP No. 2025223742-1

Sheyang Tianyuan Chemical Co., Ltd Copyright(C)2017 Network Support 思科网络 Copyright Statement Sitemap